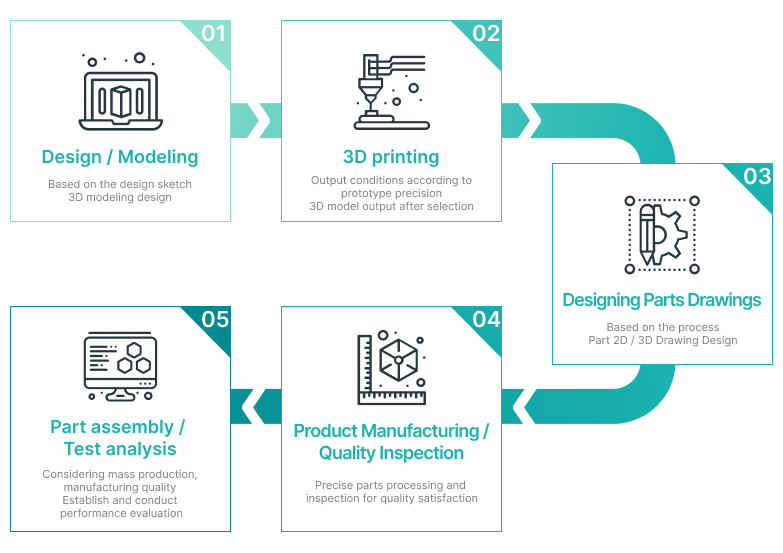

Prototype Production

• Production of prototypes based on the needs of demanding companies

*voucher support projects

• Reliability evaluation of manufactured prototypes

History of Prototypes

• 23.10 ~ 23.12 A high-efficiency motor

• 22.12 ~ 23.03 Liquid Filler Improvement Parts

• 22.09 ~ 22.12 Hard metal drawing die and plug

• 21.12 ~ 22.02 High-performance liquidsolid separator

• 21.10 ~ 21.12 Lithium-ion battery pack

• 21.04 ~ 21.06 Hydraulic coupling bolt process design and fabrication

• 21.03 ~ 21.05 BLDC Motor for Solar Water Circulation System

• 21.03 ~ 21.05 Multifunctional heated cushion

• 21.02 ~ 21.04 Integral Elbow, Integral Tee

• 21.01 ~ 21.02 Liquidsolid separator

• 22.08 ~ 22.10 XR Wide Projection Media Wall

• 21.08 ~ 21.10 Tap Changer

• 21.06 ~ 21.09 Mulberry textile sanitary pad pattern mock-up

• 20.07 ~ 20.09 3-axis instrument

• 23.04 ~ 24.03 Fixed rails for improved durability and work efficiency of functional panels

Government R&D Support

R&D History

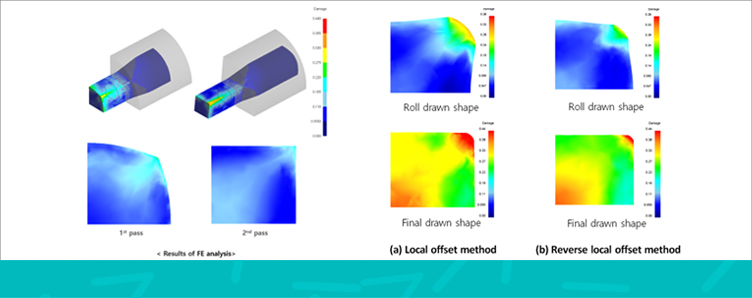

• 2017 ~ 2018 : Production of a prototype of a deformed cross-sectional shape material

using Multi-roll-die drawing molding technology

• 2018 ~ 2019 : Development and Commercialization of Core Components of Electrical Plating System

for Functional Pipes for Coated Pipe with different kind of metal

• 2018 ~ 2018 : Development of minimum thickness (≤1.5 mm) / large diameter (≥300 mm) corrosion-resistant

alloy weld pipes for reactor pump cases and establishment of corrosion reliability standards

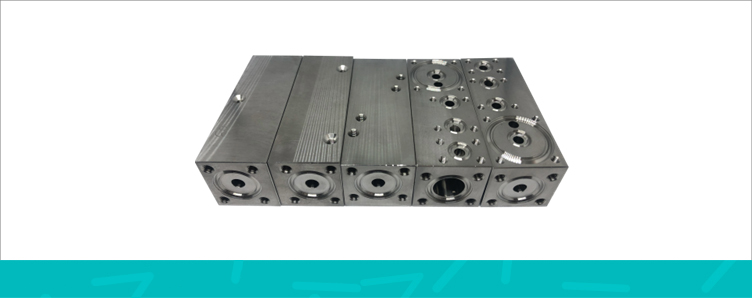

• 2018 ~ 2019 : Localization of high corrosion resistance material release cross section parts

for mass flow control

through mechanical fusion Shaped Drawing technology

• 2019 ~ 2019 : Development of automotive engine exhaust system flange manufacturing process

through high aspect ratio/composite cross-sectional drawing technology

• 2019 ~ 2020 : Development of Sustainable Metal Composite Manufacturing Process that Fuses Coated Pipe

with different kind of metal Technology and Cold Processing Technology

• 2020 ~ 2021 : Developement of Towed Interferometric Synthetic Aperture Sonar

• 2020 ~ 2022 : Localization of high-nickel equivalent stainless-steel material/part optimized with cold working and

cutting working for hydrogen transportation and charging

• 2021 ~ 2022 : Development of high-strength and high-precision housings and flanges for servo motors in robot and

automobile industries

• 2021 ~ 2023 : Development of 100kW Modular Battery Car System for Power Supply

• 2023 ~ 2024 : The localization of technical development of shape fusion machining to improve yield rate of

manufacturing process for instrumentation fittings with 95% or higher degree of

hydrogen embrittlement sensitivity

• 2023 ~ 2024 : Development of Integrated Building Finishing Materials for Fire Prevention in Buildings

with Semi-Flammable Insulation Multi-Step Bonding Technology without Adhesive

>

R&D > Order Research

>

R&D > Order Research